PT. Torishima Guna Indonesia as a manufacturer of centrifugal pumps in Indonesia has implemented standards of integrated management system, including in terms of Quality (QMS) which implements ISO 9001:2015, in terms of Environment / EMS applies ISO 14001:2015, and also the latest , the implementation of OHS / OHSMS with ISO 45001: 2018, which in 2019 has been implemented as an upgrade from OHSAS 18001 as the only SMK3 standard that applies internationally.

There is a fundamental difference between ISO 45001 and OHSAS 18001. Structurally, the ISO 45001 system aims to facilitate the process of implementing and integrating several other management systems so that they can be integrated efficiently and systematically. Then there is Organizational Context which considers the OHS aspect as an impact not only on workers but also on the wider community, namely the surrounding community. ISO 45001 demands the incorporation of occupational health and safety aspects in the overall management system of the organization, thereby encouraging top management and other departments besides the department.

OHS, to have a strong leadership role in the OHS management system. ISO 45001 also requires organizations to take into account how suppliers and contractors manage their risks.

In May 2021, PT. Torishima Guna Indonesia has carried out the ISO 45001:2018 Surveillance Audit. Among the principles that must be considered is the Organization must identify and know related issues involving K3 as the impact of business integrity and become the basis for continuous improvement to be implemented. Organizations are also required to comply with applicable regulations related to OSH, both state and city government regulations, for example by conducting regular monitoring of work areas in terms of physics, chemistry, and biology. Monitoring of noise, lighting, ISBB and vibration. To certify operators and production and utility equipment such as Crane certification in the form of SILO (Operation Proper License) and Operators who use the Crane in the form of SIO (Operator Permit).

PT. Torishima Guna Indonesia as a Manufacturing that involves a lathe / machining process has a variety of lathes, for this reason, PTP (Production Power Plane) certification must also be carried out

As supporting material transportation, we also use forklifts to facilitate material mobilization and we are committed to training certified forklift users/drivers before using them.

ISO 45001 takes a systematic and comprehensive approach to occupational safety & health. This is the answer to the question of how to prevent work accidents that occur continuously. Occupational Health and Safety is Important and a Shared Responsibility. As a form of management’s commitment to the implementation of ISO 45001:2018, we carry out an annual Management Review of all aspects of interest and risks that are integrated with the OHS & environmental system.

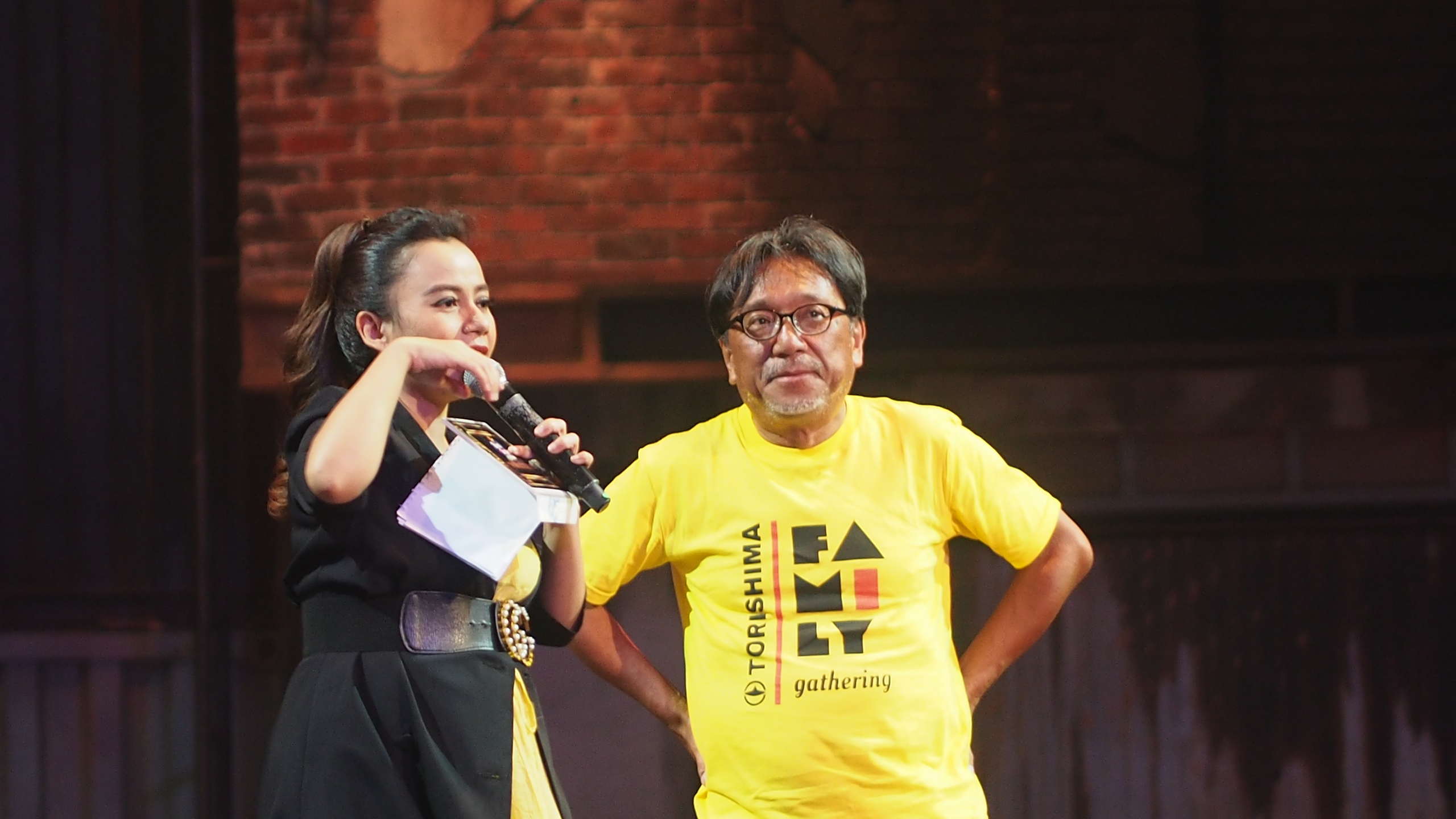

Palmex Indonesia 2023 is the ideal forum for palm oil industries in Asia that brings together an international congregation of both upstream and downstream palm oil companies and also its supporting industries to showcase the latest developments in the palm oil industry. The event, held on 4– 6th October at Santika Premiere Dyandra Hotel & Convention Medan – Indonesia, included 200 brands from 5 countries (Indonesia, Malaysia, Singapore, India, and China) more than 5000 visitors, and 3 days forum sessions to provide a platform for sharing.

Palmex Indonesia 2023 is the ideal forum for palm oil industries in Asia that brings together an international congregation of both upstream and downstream palm oil companies and also its supporting industries to showcase the latest developments in the palm oil industry. The event, held on 4– 6th October at Santika Premiere Dyandra Hotel & Convention Medan – Indonesia, included 200 brands from 5 countries (Indonesia, Malaysia, Singapore, India, and China) more than 5000 visitors, and 3 days forum sessions to provide a platform for sharing.