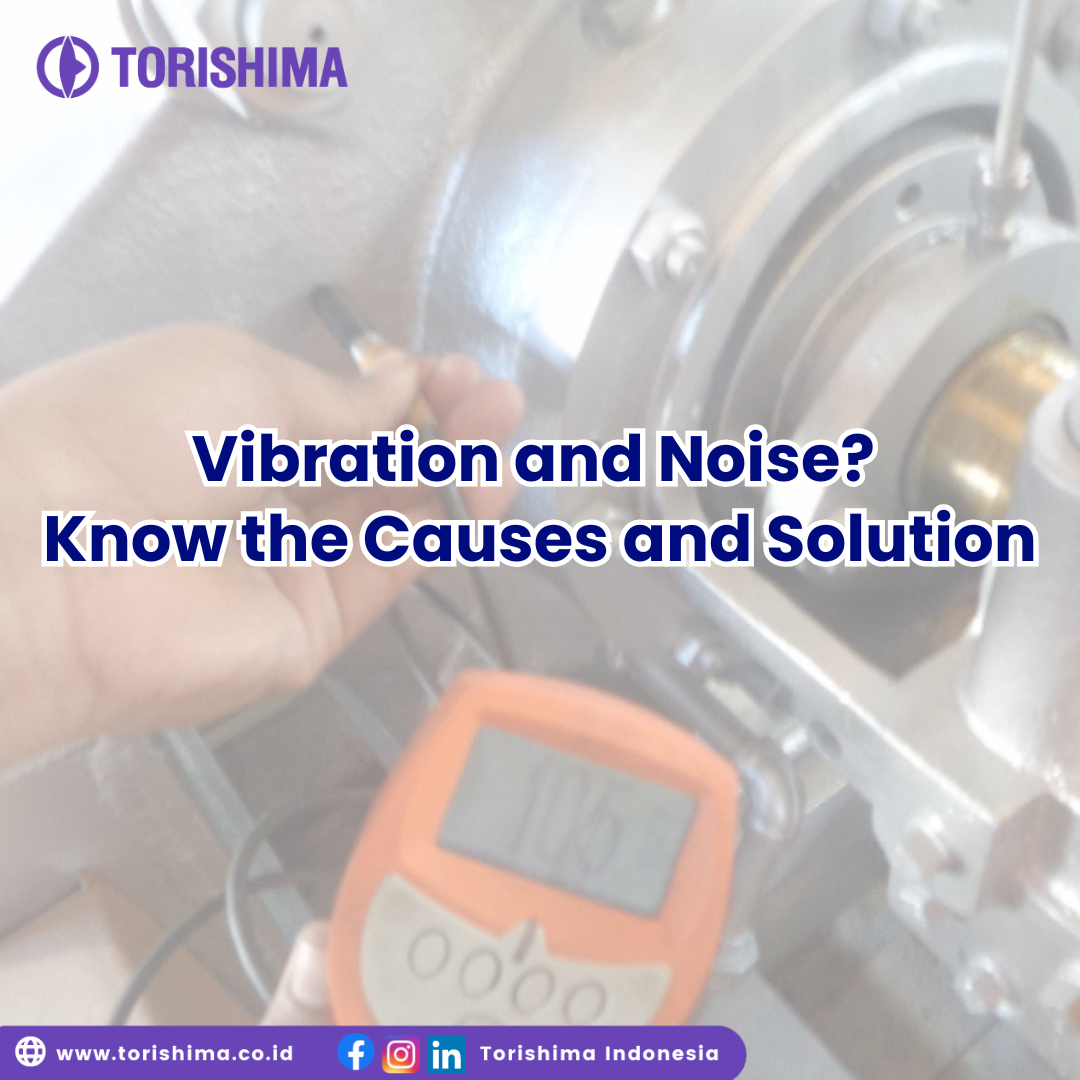

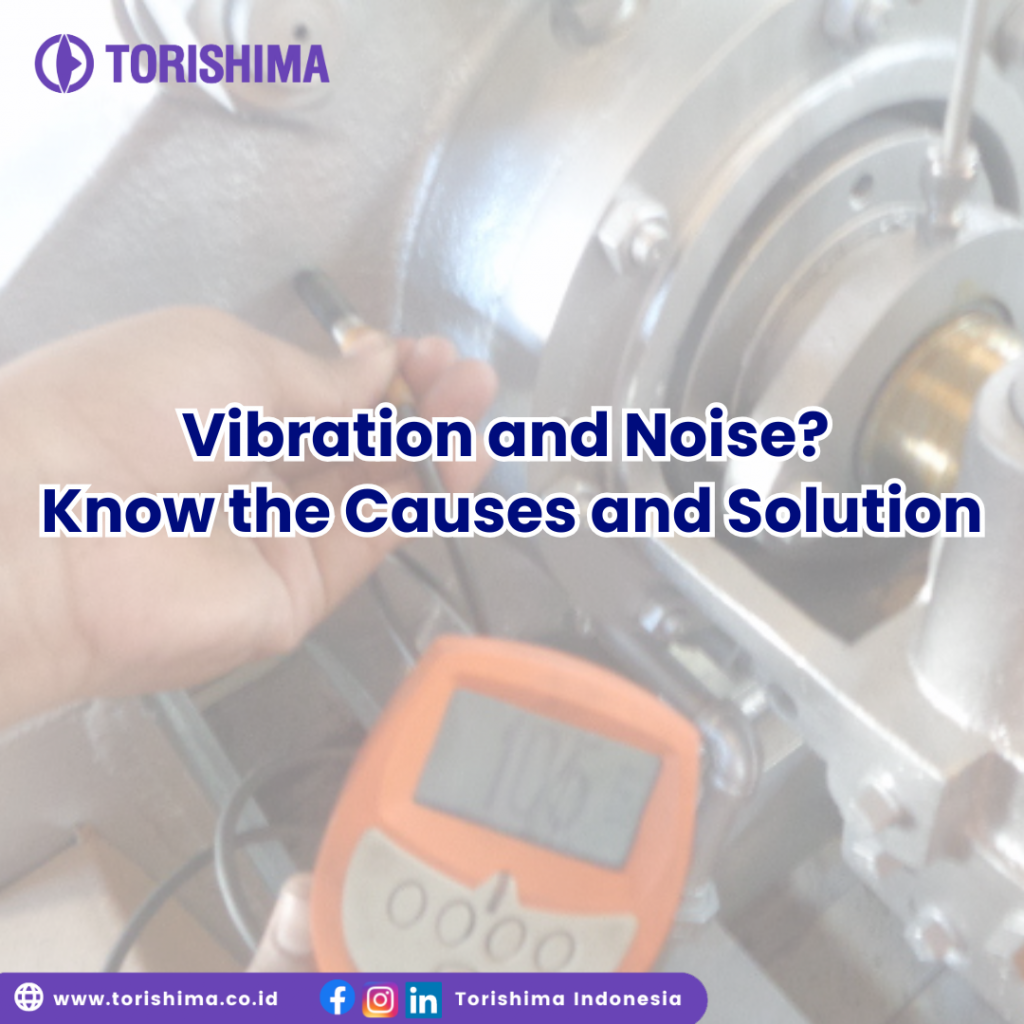

Industrial pumps that vibrate and make loud noises not only disrupt operations but can also be an early indication of damage to the system. Therefore, it is very important to identify and understand the causes and solutions to these problems to maintain performance and extend the service life of the pump.

What are the main causes?

- Misalignment, occurs when the pump shaft and motor are not aligned, causing imbalance that triggers excessive vibration.

- Cavitation, which occurs when the pressure of a liquid falls below its vapor pressure, producing air bubbles that then burst and cause a loud noise.

- Unbalance in the impeller, which can be caused by dirt, wear, mechanical damage, or manufacturing defects that cause uneven centrifugal force.

- Bearing failure, due to inadequate lubrication or wear due to age, resulting in high friction and noisy sounds.

- Loose parts, caused by loose bolts, mounts, or other components, resulting in additional vibration when the pump is operating.

- Hydraulic issues, caused by turbulent flow, where the pump operates far from the Best Efficiency Point (BEP), or head that is too high/low.

So, what can be done to solve this problem?

- Regular/periodic alignment checks of the pump using a Dial Indicator Gauge/Taper Gauge to ensure that the pump shaft and motor are aligned.

- Ensure that the suction head (NPSHa) is sufficient to prevent the pressure from falling below the vapor pressure. Avoid narrowing the flow path on the suction side. Ensure that the pump does not operate outside its design limits.

- Clean the impeller of debris and deposits on a regular basis. If necessary, replace the impeller if it has suffered physical damage.

- Replace bearings according to the maintenance schedule, use the appropriate lubricant, and inspect them regularly, as well as monitor temperature and vibration as early indicators of damage.

- Tighten loose components and inspect the condition of the support structure. Replace worn components before they cause further damage.

- Ensure the pump operates near the Best Efficiency Point (BEP). Evaluate the piping system to ensure smooth and efficient flow.

Vibration and noise in industrial pumps are generally caused by mechanical factors such as misalignment, cavitation, unbalanced impellers, bearing wear, loose or detached pump components, and hydraulic problems. By implementing routine maintenance, monitoring operational conditions, and applying appropriate technical measures, the risk of damage can be minimized and pump performance can be kept at an optimal level.

Be sure to choose a pump that suits your operational needs. Torishima offers a wide range of industrial pumps for various needs. For more detailed information about our products, visit our website torishima.co.id

Wednesday, May 28, 2025, PT Torishima Pump Mfg. Indonesia held a Medical Check Up (MCU) activity which was attended by all employees. It is hoped that through this activity, the performance of PT Torishima Pump Mfg. Indonesia’s employees can be improved by starting from a fit and healthy soul. Employee medical check-up is one of the occupational health and safety (K3) programs carried out to assess the current condition of the employee’s health while determining the employee’s ability to perform a job based on His/Her health condition. Because we believe that good employee health, supported by a safe work environment will have a positive impact on our employee’s wellbeing and productivity.

Wednesday, May 28, 2025, PT Torishima Pump Mfg. Indonesia held a Medical Check Up (MCU) activity which was attended by all employees. It is hoped that through this activity, the performance of PT Torishima Pump Mfg. Indonesia’s employees can be improved by starting from a fit and healthy soul. Employee medical check-up is one of the occupational health and safety (K3) programs carried out to assess the current condition of the employee’s health while determining the employee’s ability to perform a job based on His/Her health condition. Because we believe that good employee health, supported by a safe work environment will have a positive impact on our employee’s wellbeing and productivity.

A VS4 pump, also known as a “Vertical Sump Pump Type 4,” is a specific type of centrifugal pump used primarily in industrial applications. These pumps are designed to handle the transfer of liquids from sumps, pits, tanks, or other reservoirs that are below ground level.

A VS4 pump, also known as a “Vertical Sump Pump Type 4,” is a specific type of centrifugal pump used primarily in industrial applications. These pumps are designed to handle the transfer of liquids from sumps, pits, tanks, or other reservoirs that are below ground level.